We are proud to list a number of global brands as our customers. If you have a bespoke requirement, call us on +44 (0)1985 219032, or use the 'Get In Touch' page, to see why they chose us.

For our 'off-the-shelf' products, please click 'Buy Now' and search our catalogue.

Our Capabilities:

Design & Manufacture:

AVMR is particularly experienced in the design and manufacture of technically challenging bushes. At one extreme, we are able to hold some of the tightest tolerances in the industry for very small diameter, double and triple bonded and thin walled (lightweight) products, we do this at volume and we are cost-competitive.

At the other extreme we design and deliver one-off projects for hyper-cars, and speed record-breaking vehicles as well as in mining, rail, energy, agricultural and naval applications.

Aggressive operating environments can cause issues for rubber and rubber-bonded products, however AVMR has good experience with difficult environments such as:

- Corrosive and extreme temperature environments

- High load, vibration and shock applications

- Very long life requirements

A torsion bush bonded in place

Bush Variants:

Bushes come in a number of configurations, shapes, sizes, rubber types and rubber hardnesses, metal types and platings, bonding variants, and finishes. The final design depends on a number of factors including:

- Environmental conditions

- Energy absorption in each axis

- Allowable displacement in each axis (individual degrees of freedom can be partially or fully restrained if necessary)

- Fixing or clamping method and forces

If you have a bespoke requirement, call us on +44 (0) 1985 219032 to see if we can help.

Innovative Manufacturing:

AVMR's in house design team has developed and built a modular tooling system which allows most of our bushes to be manufactured without the requirement for full tooling to be purchased.

This innovative system reduces setup costs and enables reduced time to market due to the simplicity of the product specific element of the mould tool.

"All of the 'thinking' was done upfront, so your experience with us will be simple."

The complexity of the technical requirements to prepare substrates for bonding normally surprises even the most experienced Engineers visiting our site. We have been delivering the process, and investing in capability and efficiency, for decades.

We use an uncommon 3-4 stage substrate preparation process which prolongs bond integrity, especially in more aggressive environmental conditions, when compared to more common bonding approaches.

General Information

Engineering Bushes is a fairly generic term, these may also known as:

- Bushings

- Torsion bushes

- Spherical bearings

The most common application for bushes is in vehicles for steering racks and suspension arms.

They are commonly used in automotive and rail applications for suspension system linkages or leaf spring mounting, where some degree of movement within a connection is desirable.

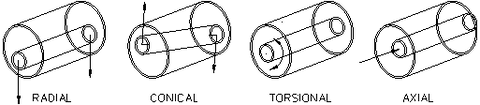

This bush design provides for displacement in a combination of radial, axial, torsional or conical loadings (see diagrams below)

Bushes are placed at pivot points for any of the following reasons:

- Smooth and predictable movement without the wear associated with solid metal bushes. No surface to surface sliding motion for any required motion.

- Deflection under load - when engineered into a system, this deflection can allow the linkage freedom of movement. If deflection is not accommodated within the torsion bush, stresses may be transferred to other mechanical components.

- Modern suspension systems are designed so that the bush deflection does not seriously impact alignment, allowing for vibration isolation whilst maintaining the steering geometry

Radial

This relates to displacement such that the inner tube is moved towards the outer tube whilst remaining axially parallel to it such that the thickness of rubber is reduced uniformly on one side.

The radial displacement can be decreased by increasing the projected area (diameter of inner tube x length of outer tube). This can be facilitated by increasing the overall length of the bush or by increasing the outside diameter of the inner tube.

When only radial loading is anticipated, these bushes will withstand significant shock loads in excess of normal rated load for the size (up to 5 times rated loading) However, if conical loading is anticipated in addition to radial loading, the nominal rated loading must be reduced. Also if cyclic loading is anticipated, the load catered for should be at least halved.

Torsional

When one tube is rotated relative to the other whilst remaining axially parallel, this implies a torsional load. Reducing the thickness of the elastomer will reduce the angular displacement for a given torque (increasing the inner tube’s outer diameter or decreasing the outer tube’s inner diameter) or by increasing the overall length of the bush.

Typically the maximum frequency of torsion loading accommodated is 8Hz (480 cycles per minute) and this would be for small angular movements up to +/-5 ° For lower frequencies +/-40° can be accommodated for some bushes where the rubber thickness allows.

Conical

If an angle is developed between the axes of the two tubes such that they are no longer parallel, this is a conical load.

The displacement from such loads can be minimised by reducing the thickness of the elastomer or by increasing the length of the bush as above.

Applications should limit the angular movement such that the thickness of elastomer at the end of the outer sleeve is not reduced by more than 30%. Clearly, greater conical movement is provided by a greater thickness of elastomer, which in turn can be determined by changes in tube diameters.

Axial

When the ends of the tubes are displaced relative to their no-load position whilst the axes remain parallel, this is an axial load. The displacement can be reduced by reducing the thickness of the elastomer or by increasing the length of the bush as above. Design loads should be kept to a maximum of 10% of the rated radial load.

The deflection parameters can also be modified by altering the hardness of the elastomer (harder reduces deflection) or by inserting an intermediate tube which reduces deflection in all directions as for example in our TB (triple bonded) bush type.

Installation

For standard bushes, the outer tube is normally either clamped in place or is an interference fit in a machined housing requiring insertion using a mechanical or hydraulic press. The inner tube is typically held in place by a clamping bolt which is tightened to sufficient torque to prevent the inner tube from rotating in use under the forces likely to be experienced.

In some heavier applications, bushes might use a solid 'dog bone' style innertube with machined fixture points. This is very common in rail applications where additional features can prevent movement in one or more axes.

Press Fit Tolerances on Bores

In most applications bushes are intended to be a press fit in a bore. In this case the following bore tolerances should be applied: The bush diameter should be taken as its nominal size – mid-tolerance.

Note: where the bush is to be inserted into a rolled spring eye, the interference is greater due to the yielding of the spring eye.

|

Outside diameter of bush (mm) |

Bore limits from nominal bush O/D |

Rolled Spring eye Bore |

SAB Style Bushes |

|

6 to 23 |

-0.04 / -0.06 |

-0.25 / -0.50 |

-0.25/ - 0.35 |

|

24 to 40 |

-0.05 / -0.08 |

-0.40 / -0.70 |

-1.00 / -1.10 |

|

41 to 50 |

-0.06 / -0.09 |

-0.9 / -1.10 |

-1.50 / -1.60 |

|

51 to 70 |

-0.08 / -0.0.10 |

-1.00 / -1.40 |

-1.70 / -1.80 |

For SAB style bushes without the outer steel tube, the degree of interference is also much greater. This provides for security of installation and also has the effect of stiffening the bush due to the compression of the rubber during assembly.

Call us on +44 (0)1985 219032 if you would like to discuss a requirement you have, or get in touch via the 'Get In Touch' page.