We are proud to list a number of global brands as our customers. If you have a bespoke requirement, call us on +44 (0)1985 219032, or read below to see why they chose us.

For our 'off-the-shelf' products, please click 'Buy Now' and search our catalogue.

Quote from a customer who we worked with to design and manufacture a heavy duty bespoke track pad:

"After a comprehensive review of the market, we selected AVMR as they could offer manufacturing capabilities, a technically compliant product, with good design input, and at a cost-effective budget. We've built a good relationship with AVMR, and would be keen to work with them again in the future"

- A multi-discipline engineering company providing solutions to the Oil & Gas sector.

Our Capabilities:

Design & Manufacture:

AVMR has 35 years' experience designing and manufacturing track pads and haul-off pads, and we have developed cost-efficient methods of delivering low-medium volumes.

We have geared all aspects of our business around low-medium volume production. We use low-cost tooling and have the rubber moulding expertise to make this work; large cross-section rubber and rubber-metal bonded components are challenges we are happy to take on when many others would not.

Aggressive operating environments can cause issues for rubber and rubber-bonded products, however AVMR has good experience with difficult environments, such as:

- Corrosive and extreme temperature environments

- High load, vibration and shock applications

- Very long life requirements

Innovative Manufacturing:

Using the lowest cost production processes to mould large cross-sections of rubber is challenging, doing this for a bonded product is even more so. AVMR uses a number of process techniques and tailored rubber formulations to ensure that a robust product results.

The complexity of the technical requirements to prepare substrates for bonding normally surprises even the most experienced Engineers visiting our site. We use an uncommon 3-4 stage substrate preparation process which prolongs bond integrity, especially in more aggressive environmental conditions.

We are proud to list a number of global brands as our customers. If you have a bespoke requirement, call us on +44 (0)1985 219032, or read below to see why they chose us.

General Information:

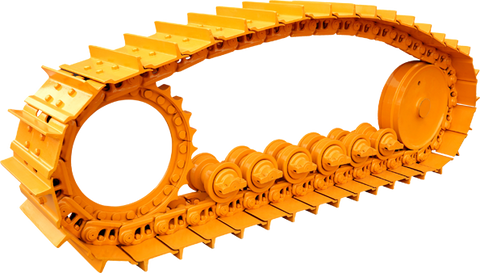

Track pads are used on Caterpillar tracks, also called 'tank treads' or 'continuous track', and on conveyor belts and they are often called Haul Off Pads or Gripper Pads. Below is an example of a standard caterpillar track used on mobile machines before installation of our rubberised pads. Unfortunately we do not currently have an image we are allowed to use of a relevant catepillar track with our rubber pads on it.

These tracks are also used in stationary applications e.g. where they are used to push, pull or to brake pipework or cables whilst being spooled or laid. These are often the more aggressive applications; it is not unusual for individual pads to take 10-40 tonnes in compression plus 5-10 tonnes in shear.

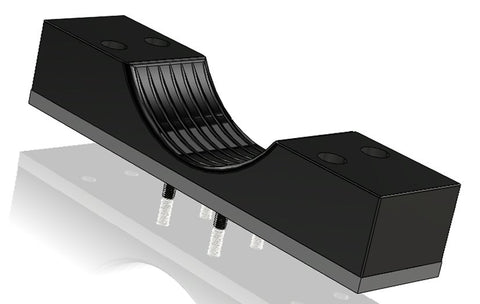

Haul Off pads are very similar to track pads, however rather than having to apply forces to drive or control a speed, a haul off pad is generally used immediately after a continuous moulding process (e.g. extrusion) to provide support to the newly formed product whilst moving with the product to avoid friction between the surfaces. Accuracy of profile, and the use of low friction rubbers can be key for haul off pads.

A standard caterpillar track used on mobile machinery (not rubberised)

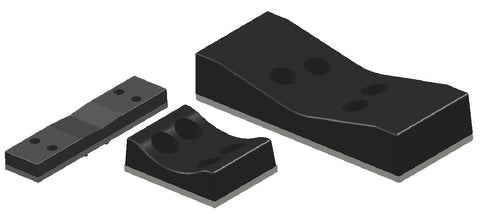

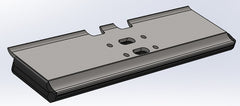

One of our projects was to design and supply a track pad which could directly replace the metal tracks on a machine already in place, and similar to the above. The result was the below pad.

A rubberised track pad for a mobile application

Whether it is a caterpillar track or conveyor belt, the track itself is normally made up of a continuous chain of metal plates; depending on the use, these might not be the best solution:

- Standard tracks are notoriously abrasive and damage road surfaces. Something with a softer contact point will result in less damage to the road.

- If two counter-rotating tracks are being used to feed, draw, or brake (to control feed speeds) large diameter pipe and cable, grip is a critical design requirement. Softer track surfaces deform around the pipe or cable when squeezed thereby enabling that squeeze load to be distributed evenly and reducing potential for damage.

- As some products are manufactured, they need well distributed support which is often across a complicated profile (e.g. in extruding upvc window profiles. A conveyor belt track pad shape which has been formed to match the product profile can offer the required support.

- Conveyor belts will often have loads dropped onto them. A level of shock absorption can be offered by softer surfaces which lengthen equipment lifespan.

For all of the above applications, a rubber or rubber and metal sandwich construction of track pad are more likely to offer a suitable solution.

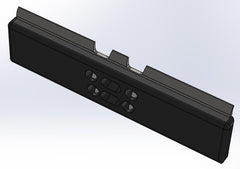

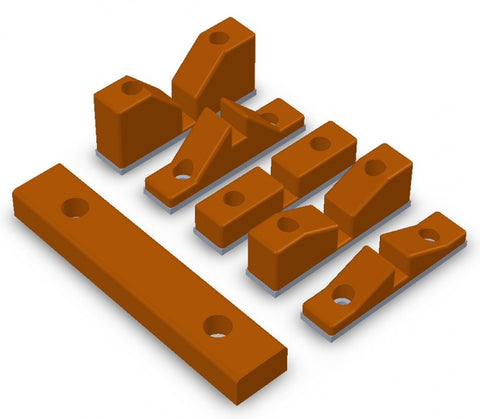

Plastic Extrusion Haul Off Pads - use on static machines

We have designed and manufactured pads from 500g to 18kg, and pride ourselves on the niche sector knowledge that we have. We believe that in this field there are few, if any, competitors of a similar size who offer the material and bonding expertise along with the manufacturing capabilities that we at AVMR have.

A haul off pad for a static application e.g. laying cable or pipework

All of our current track pads have been developed for bespoke requirements. They have been developed in partnership with the customer, and are unlikely to be suitable for sale via the online shop.

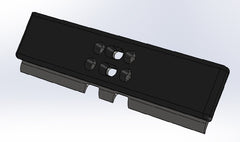

A Haul Off Pad for extrusion of a specific pipe diameter - used on a static machine. The pipe in this example was circa 18 inch diameter.

Smaller pads used on extrusion lines are commonly found on the following machines: Actual, Barrufaldi, Bergsmann Amut, Cincinnati, Ide, Speedex, Technoplast, Uniplast and Vobau.

Here is an example of a small haul off machine:

If you would like to discuss a requirement you have, please get in touch via the 'Get In Touch' page.